The stiffness of racing shells can be measured and compared with a few simple tests. The structural stiffness of a racing shell is important; if a boat’s structure deflects under load (when the rower pulls), then it is absorbing energy that would otherwise be available to propel it. A stiffer system transmits power to hull speed more efficiently.

Stiffness testing quantifies a boat’s structure and allows comparison of one boat to another in meaningful ways. Following extensive structural engineering work, Pocock developed the new Hypercarbon laminate, and compared its stiffness to other well regarded boats. All of the boats were tested for longitudinal and torsional hull stiffness. And because hull stiffness alone does not truly indicate how stiff the boat feels to the rower, a third test was added to measure deflection at the oarlock under a simulated rowing load.

Longitudinal stiffness (hull flexure over its length) has long been the classic quantifier for stiffness because it is easy to measure. The East Germans were doing longitudinal stiffness tests back in the mid-1970s, and coaches have been grabbing the ends of boats and shaking them from time immemorial. These are informal longitudinal bending tests based on the improbable assumption that a boat stiff in one dimension is stiff overall.

Torsional stiffness (hull twisting) has not been measured in any way that we are aware of outside of Pocock Racing Shells. Pocock has been doing formal longitudinal and torsional bending tests since 1987, firmly believing that stiffness in both dimensions is more indicative of overall stiffness.

But even these two tests together are not the best indication of a boat’s stiffness. Both tests assume that the outriggers are infinitely stiff, which of course, they are not. The way the riggers attach to the boat, or the way the riggers are supported in the hull, definitely affects the system’s stiffness. Therefore, the truest and most meaningful test of a boat’s overall stiffness is the Rigger/System Flex Test, measuring the deflection of the loaded oarlock.

Goals

Our purpose in conducting these tests is to discover differences in stiffness between:

- Pocock’s new Hypercarbon boats and other well regarded boats, specifically Vespoli (Ultralight, Millennium, and M2), Empacher and Resolute.

- Pocock’s new Hypercarbon laminate and old laminate.

Methodology

Longitudinal Bending Test:

The boat is fixed upside down on two hard supports, one at the aft end of the cockpit and one in the middle; 10 kg and 20 kg weights are hung at the forward end of the cockpit. Deflection is measured at the forward end of the cockpit. Two weights are used in order to check the linearity of the deflection and to get enough total deflection for easily discernible measurements. In order to accommodate all the various boats in this test series, and to insure equal bending moments, the aft and middle supports were placed 18’ 0” apart, and the weights were hung 16’ 1” forward of the middle support.

Torsional Bending Test:

The boat is fixed at the stern end of the cockpit and a torque arm with a center pivot is attached at the bow end of the cockpit; 10 kg and 20 kg weights are hung on the arm, 30” from the center, and deflection is measured there. All the boats were tested with the torque arm 34’ 1” forward of the fixed aft support.

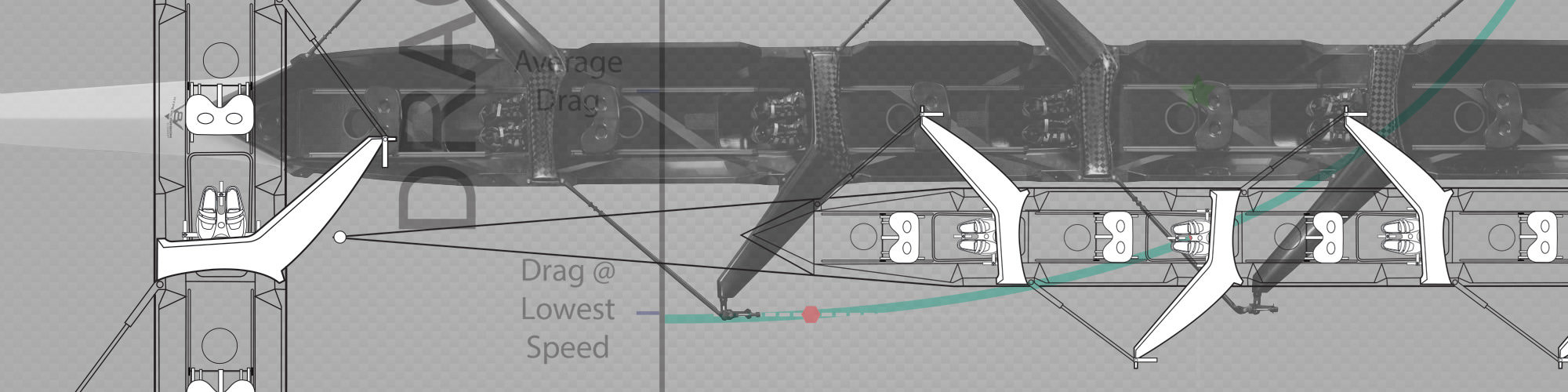

Rigger/System Flex Test:

With the boat upright in slings, a 240 lb. pulling force is applied via a block and tackle arrangement between the top of the pin of the #6 rigger and the bottom of the pin of the #5 rigger, thus applying a forward diagonal load (similar to the force at the catch). Deflection is measured between the pins, i.e. parallel to this tensile force.

Results

The results are presented in the following table. All boats were weighed on the same scale and weighed fully rigged. Listed weight subtracts 4 lb. adjustment for cox box set up. Note: LESS DEFLECTION INDICATES MORE STIFFNESS

| Boat | Weight | Longitudinal Deflection | Torsional Deflection | Rigger Deflection |

|---|---|---|---|---|

| Pocock V8 (small hull) Hypercarbon Laminate |

203.5 lb | 10kg: 6.5 mm 20 kg: 16 mm |

10kg: 13.0 mm 20 kg: 28.5 mm |

4 mm |

| Pocock V8 (large hull) Pre- H.C. Laminate |

208 lb | 10kg: 12 mm 20 kg: 24 mm |

10kg: 16.5 mm 20 kg: 37 mm |

6.4 mm |

| Resolute Heavyweight Eight | 206 lb | 10kg: 9.5 mm 20 kg: 16 mm |

10kg: 14.5 mm 20 kg: 28.5 mm |

12.5 mm |

| Vespoli M2 DXL | 209 lb | 10 kg: 5 mm 20 kg: 11 mm |

10 kg: 19 mm 20 kg: 41 mm |

19 mm |

| Vespoli Millennium DXL Eight | 211.5 lb | 10kg: 6.5 mm 20 kg: 13.0 mm |

10kg: 22.0 mm 20 kg: 44.5 mm |

11 mm |

| Vespoli Ultralight DXL Eight | 220 lb | 10kg: 9.0 mm 20 kg: 16 mm |

10kg: 22.0 mm 20 kg: 43.5 mm |

10.5 mm |

| Empacher K85 Heavyweight Men’s Boat (Sectional) | 215 lb | 10kg: 9.5 mm 20 kg: 19.0 mm |

10kg: 12.5 mm 20 kg: 28.5 mm |

9.5 mm |

Conclusions

Pocock’s development of the Hypercarbon laminate was successful and worthwhile:

- Comparison of the differences in stiffness between the new Hypercarbon laminate and the old laminate has shown that the new boat is stiffer.

- While the new boat is a few pounds lighter, it demonstrates significant improvement in stiffness.

- The new boat is almost twice as stiff longitudinally, 22% stiffer in torsion and has 38% less rigger deflection.

Pocock boats compare favorably to other manufacturer’s boats:

- Longitudinal Bending Test -The closest results between all of the boats are in longitudinal stiffness. This is not surprising as it is the most frequently assessed criteria for stiffness and the highest priority of most manufacturers.

- Torsional Bending Test – The results for this test are also very similar across all boats with the exception of the ribbed boats (Vespoli Ultralight and Millennium). It is evident that the full length pan, a design developed by Pocock and now seen in the Resolute and Vespoli M2, is a highly successful element for structural stiffness.

- Rigger/System Flex Test – The greatest discrepancies between boats are found in testing the system’s stiffness under load. Pocock’s wing rigger, bolted across the gunwales, is a structural stiffening element and exhibits by far the least flex of all boats. In other boats it was discovered that in some cases (i.e. Resolute) the riggers are the flexible element, moving up and down during the load cycle. In other cases (i.e. Vespoli) it is the gunwales that flex under load. Gunwale flex is most apparent in the M2, which has almost twice the deflection of the other Vespoli models.

Interesting notes regarding comparisons:

One of the few restrictions boat builders have is the minimum weight requirement. Because stiffness is so important, builders use as much material as possible to make the boats stiff. While it makes perfect sense that a heavier boat (made with more materials) should be stiffer, the results show that this is not always the case. Where it is placed and how it is aligned is critical. What makes the Hypercarbon laminate stand out is how placement of the materials is optimized for maximum stiffness.

Generally men’s boats, being bigger and deeper than women’s boats, are stiffer. Geometrically speaking, a deeper boat is longitudinally stiffer than a shallow boat, and a wider boat is torsionally stiffer than a narrow boat. It is interesting to note that all of the comparison boats were big men’s boats except Pocock’s, which was further geometrically disadvantaged by the notched wing saddles in the gunwales, effectively reducing the beam depth by 2″.